Rubber gasket Daily life rubber products Rubber sealed loop Stabilizer for industrial use

Huizhou DOIT Precision Products Co., Ltd. is an emerging enterprise integrating quality management and production technology from Japan and Taiwan. The main backbone members have more than 8 to 20 years of experience in mold design, material formula selection and application, production and quality management, and customer management. With working experience and OEM and ODM cooperation experience with many Fortune 500 companies, DOIT is a professional manufacturer that combines the design, manufacture and sales of silicone rubber molds and silicone rubber products.

DOIT is dedicated to the development, manufacture, sales and provision of customer technical services for precision rubber seals, silicone rubber watch straps and precision silicone rubber products. Our flat management can respond quickly to customer needs, employees have a good working environment, production efficiency and quality control have been recognized by customers for a long time, and we have always held the business philosophy of common development with customers. Customers establish a win-win long-term cooperative relationship.

DOIT's customer base is mainly concentrated in Japanese and European companies, and has been unanimously affirmed by customers in terms of product quality, manufacturing technology, delivery time, cost price and service.

DOIT is not just a manufacturer of good quality rubber parts. From the initial conception of the product to the final product, our technicians will cooperate with you and provide professional services in engineering design, material selection, product production and other aspects according to your different needs to ensure the applicability and quality of the product. Feature.

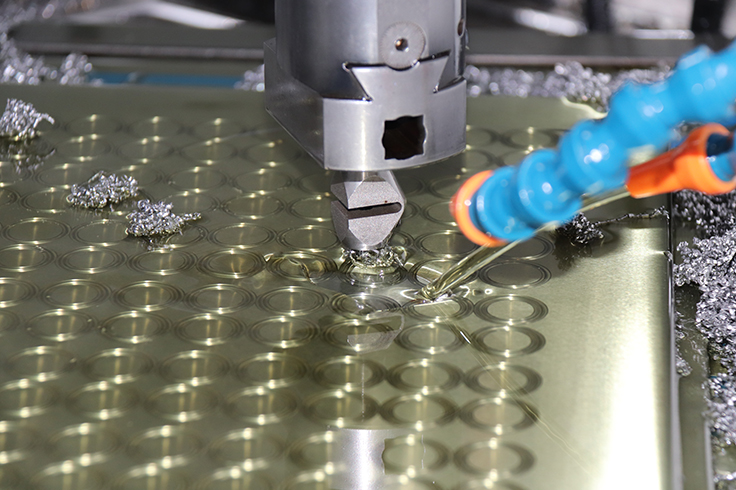

We have our own mold processing center to make molds for production. Our molds can be used to open molds and produce rubber parts according to the shrinkage characteristics of different materials, so as to control the product size and ensure its accuracy. We take this process technology and equipment further to produce miniature seals. The O-ring tolerances produced can reach half the stricter standard than AS568, and the tolerances of customized rubber parts are also stricter than ISO3302-1 M1 grade. more stringent.

A clean room is a special production or manufacturing environment designed to minimize or completely eliminate the presence of dust, particles, bacteria and other pollutants in the air. The 100,000-level dust-free workshop is a dust-free workshop with a high degree of cleanliness, and its air cleanliness level has reached the 100,000-level. This level is usually suitable for some industries with high environmental cleanliness, such as electronics, medical treatment, food, etc.

Miss Bai

15323527607

15323527607

sales5@doitrubber.com

sales5@doitrubber.com

Miss Wang

15913741299

15913741299

sales10@doitrubber.com

sales10@doitrubber.com

Mr. Wei

18566141443

18566141443

sales3@doitrubber.com

sales3@doitrubber.com

Miss Ji

15323525917

15323525917

sales1@doitrubber.com

sales1@doitrubber.com

Miss Zhou

15323536325

15323536325

sales12@doitrubber.com

sales12@doitrubber.com